Господдержка предприятий-производителей строительных материалов

Australian scientists have converted used PCBs, glass and plastic from monitor screens into a hybrid coating. For this, electronic waste was crushed and heated in an inert atmosphere. The resulting coating improved the mechanical properties of the steel: its hardness was increased by 125 percent. The research is published in the ACS Omega journal.

Usually, the same materials are produced from recycled materials: glass is made from glass, and plastic is made of plastic. However, electronic waste is made up of many components that are difficult to separate. Exposure to high temperatures in the absence of oxygen, which breaks down toxic components, can turn such waste into useful materials.

Rumana Hossain and Veena Sahajwalla of the University of New South Wales have proposed a way to recycle electronic parts and create a steel-hardening coating. The authors chose to recycle glass from old computer monitors, a plastic case, and circuit boards, which are 40 percent metal (mostly copper), 30 percent organic, and another 30 percent ceramics.

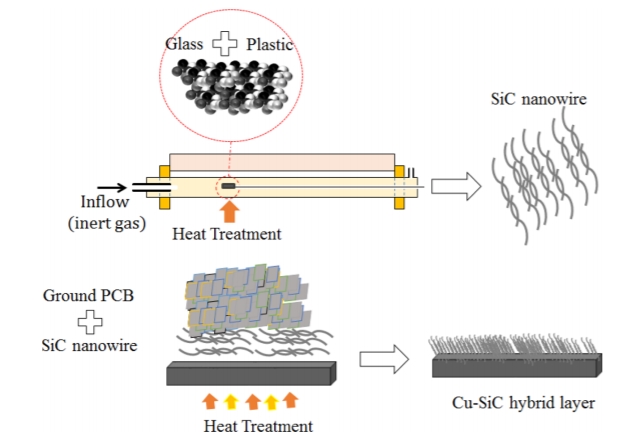

Glass and plastic were ground into powder and heated for half an hour at a temperature of 1500 degrees Celsius in an inert atmosphere. As a result, the researchers obtained silicon carbide nanowires and carbon residues, which were then mixed with crushed printed circuit boards, applied to a steel plate and kept for 15 minutes at 1000 degrees Celsius. The authors investigated the chemical composition, structure and mechanical properties of the recycled material.

Experiment scheme. In the first stage, the researchers obtained silicon caride nanowires, and in the second they mixed them with printed circuit boards and, when heated, obtained a hybrid coating.

When exposed to temperature, the plastic collapsed to form a carbon-rich gas. The carbon bonds were broken, and the atoms reacted with the main component of the glass, silicon dioxide. Then silicon monoxide interacted with carbon, resulting in the formation of SiC carbide. The nanowires grew until the vapor was saturated with silicon and carbon monoxides.

When mixed with crushed boards and applied to a steel substrate, the organic component of the printed circuit boards began to decompose at a temperature of 300-400 degrees Celsius to form carbon-containing gases. At temperatures above 720 degrees, steel could dissolve more carbon, which led to the diffusion of these gases. At 1000 degrees, copper began to melt, and a Cu – SiC hybrid layer formed on the steel surface.

Elemental analysis by energy dispersive spectroscopy indicated a uniform distribution of copper, silicon, aluminum and carbon in the hybrid layer. The surface was found to be free of cracks, scratches or cavities, and the coating was firmly attached to the steel substrate. The hybrid layer increased the hardness by 125 percent compared to pure steel: the average surface hardness was 12 gigapascals. The effective modulus was 248 gigapascals.

According to the authors, further development of the presented technology will make it possible to recycle parts of electronic devices, creating coatings suitable for use in production.

Scientists recently found a way to extract precious metals from printed circuit boards. The porous polymer material could adsorb up to 99 percent of the precious metals contained in the board solution.